183-6235-6679

183-6235-6679 183-6235-6679

183-6235-6679

优势--945楼层板成型机

• 高强度,经久耐用

此设备机架采用国标300/350工字钢,各组件、标准件一律采用国标产品,绝无空心轴等省料现象。设备运行稳定、操作简单,能充分保障您的生产进度。

• 加工工序精细复杂

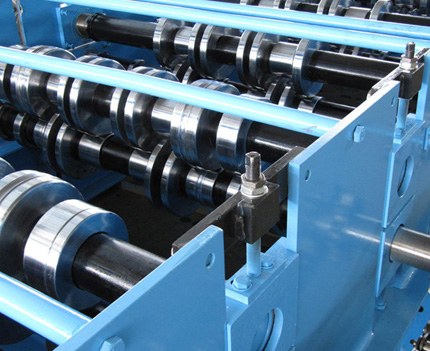

此设备压制辊轮经数控粗加工、淬火、二次精车、电镀等多步工序,精度高,跳动小,强度高,成型美观,无刮伤,无变形,充分保障您的产品质量。

• 交货快,售后积极

此设备交货期一般为35天,整机保修一年,终身维护。

规格--945楼层板成型机

|

序号 |

主要组件 |

规格 |

备注 |

|

1 |

轴 |

调质45钢 |

28道 |

|

2 |

辊轮 |

轴承钢 |

|

|

3 |

墙板 |

A3钢(18-20mm) |

|

|

4 |

传动 |

链条或齿轮箱 |

|

|

5 |

切断 |

液压剪切 |

|

|

6 |

电机功率 |

30KW |

|

|

7 |

控制系统 |

松下PLC,安川变频器 |

|

Main technical specification

1. Coil width: 1400mm

2. Material thickness: 0.7mm-1.2mm

3. Main shaft diameter: 100mm

4. Forming speed: 0-15m/min

5. Roll station: 35stations

6. Main power:2*11kw

7. Hydraulic power:7.5 kw

8. Control system: PLC Panasonic

9. Drive: by double chains

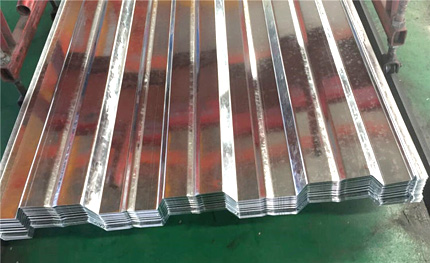

Specification of the material

1. Suitable Material: PI/ PPGI

2. Width of the raw material: 1000mm

3. Thickness: 0.8mm-1.5mm

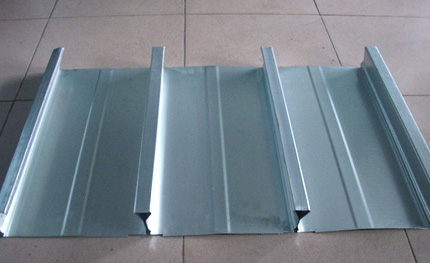

Profile drawing

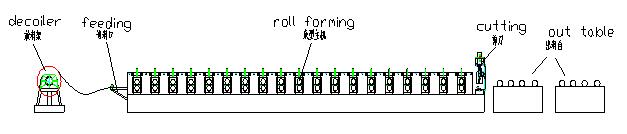

The Chart of Process Flow

Decoiler→ Feeding→ roll forming→ post cutting →out table

Machine Detailed Parameters

|

1 |

Coil width |

1000mm |

|

2 |

Rolling Speed |

0-15m/min(not include cutting time) |

|

3 |

Rolling Thickness |

0.8-1.5mm |

|

4 |

Control System |

PLC (Panasonic) as list in the note |

|

5 |

Un Coiler |

5T manual de-coiler |

|

6 |

Roller Stations |

34 stations |

|

7 |

Roller Material |

45# forge steel surface with chrome |

|

8 |

Shaft Material and DIA |

¢90mm, material is 45# forge steel |

|

9 |

Maim Motor Power |

22kwx2 |

|

10 |

Hydraulic Station Power |

7.5kw |

|

11 |

Hydraulic Pressure |

16Mpa adjustable |

|

12 |

Post cutting system |

Machine adopts hydraulic cutting system |

|

13 |

Material Of Cutting |

Cr12, 58-62 HRC hardness |

|

14 |

Structure Of The Stations |

Wall panel |

|

15 |

Electric Source |

380V, 50HZ,3 phase According to customer’s require |

|

16 |

Way Of Drive |

By chain |