183-6235-6679

183-6235-6679 183-6235-6679

183-6235-6679

成型工艺

放料——校平——冲孔——成型——定尺、切断——收料台

设备性能

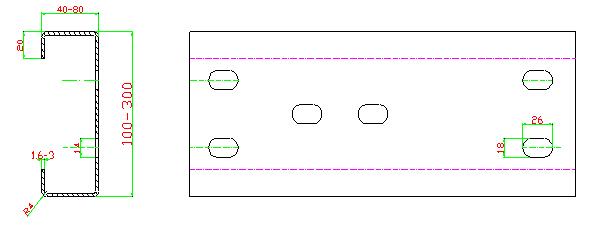

1、机组轧制能力:宽:100-500mm,

2, 板材厚度1-3mm

3、生产速度:0-15米/分钟

4、装机总容量:大约35.5kw

5、生产占地面积:长18米X宽3米

6, 电压:380V/415V,50Hz, 3相

我公司生产的设备有以下几个优点:

1.设备控制为PLC控制,在正常生产时设制多重安全保护。

2.床身为钢板焊接件。并作回火处理,消除内应力、避免机身的变形。

3.成型机架为铸铁结构,并经回火处理。强性高,使用寿命长。

4.轧辊轴的材料为40Cr,并经调质处理,硬度为HB280。

5.成型模具的材料为GCr15, 淬火处理,硬度:HRC56-62℃。

6.传动结构为齿轮箱传动。每一个成型机架都有一个齿轮箱,可保证设备超时间,高强度运行,并且使用寿命长。

Main technical specification

1. Coil width: base on profile

2. Material thickness: 2.0mm-3.0mm

3. Main shaft diameter: 76mm

4. Forming speed: 0-15m/min

5. Roll station: 15stations

6. Main power: 18.5kw

7. Hydraulic power:11kw

8. Control system: PLC Panasonic

9. Drive: by gear box

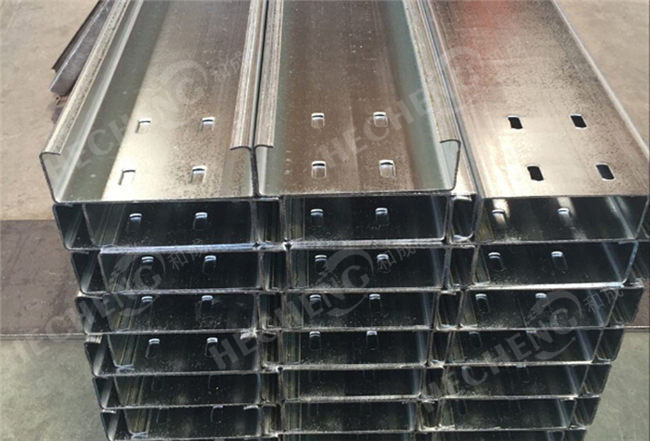

C Purlin automatic adjustable roll forming machine

Specification of the material

1.Suitable Material: Carbon steel

2.Width of the raw material: according to the final profile

3.Thickness: 1.5mm-3.0mm

Profile drawing

The Chart of Process Flow

Hydraulic decoiler→ Feeding→flatten →guide→punching→cutting→roll forming→correction adjust→output table

Machine Detailed Parameters

|

1 |

Coil width |

According to the final profile |

|

2 |

Rolling speed |

0-15m/min(not include cutting and punching time) |

|

3 |

Rolling thickness |

1.5-3.0mm |

|

4 |

Control system |

PLC (Panasonic) as list in the note |

|

5 |

De-coiler |

3 TON hydraulic de-coiler |

|

6 |

Flatten roller |

Upper us 3 rollers, down is 4 rollers |

|

7 |

Feeding and flatten drive power |

4kw, AC motor |

|

8 |

Punching and cutting mode |

Machine adopts pre-punching and pre-cutting |

|

9 |

Machine stand |

Iron cast structure |

|

10 |

Roller stations |

About 16 stations and one correction adjust system |

|

11 |

Roller material |

Ccr15, chrome plated surface with hardness 58-62 degree ,CNC |

|

12 |

Shaft diameter |

45# forged steel, φ76mm |

|

13 |

Maim motor power |

15kw, AC motor |

|

14 |

Adjust flange and width moto |

1.5KW x3 |

|

15 |

Hydraulic station power |

5.5kw |

|

16 |

Hydraulic pressure |

16-20Mpa |

|

17 |

Material of cutting |

Cr12Mov |

|

18 |

Tolerance |

3m+-1.5mm |

|

19 |

Electric source |

380V, 50HZ,3 phase |

|

20 |

Way of driving |

By chain |

Z purlin roll forming machine adopt new station to increase the firmness of the machine; and the machine adopt gearbox transmission to ensure machine working more stable; Machine adopt after-cutting to ensure quality of the cutting position of product very smooth ; products are widely used in steel structure building.

Main Technical Specification:

①Thickness: 1.5-3.0mm

Speed: 15m/min (not include cutting and punching)

Roll station: 18 stations

Main power: 15KW

Hydraulic power: 5.5KW

Control system: PLC Panasonic

Drive: by chain

Automaticity:semi-automatic / automatic