183-6235-6679

183-6235-6679 183-6235-6679

183-6235-6679

优势--950琉璃瓦成型机

• 高强度,经久耐用

此设备机架采用国标300/350H型钢,各组件、标准件一律采用国标产品,绝无空心轴等省料现象。设备运行稳定、操作简单,能充分保障您的生产进度。

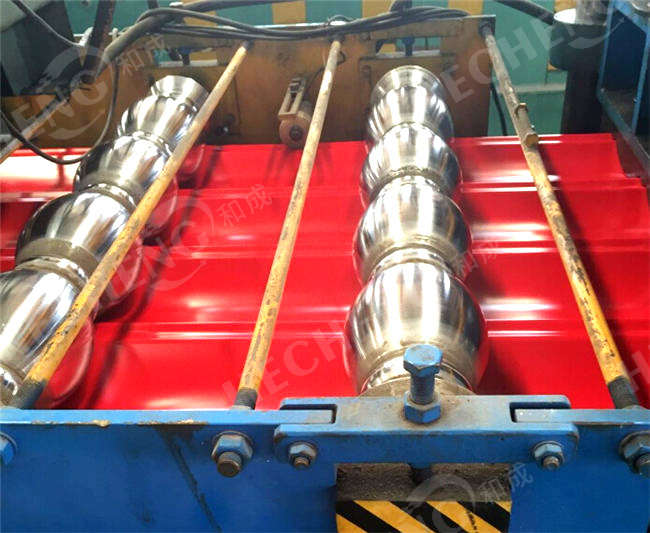

• 加工工序精细复杂

此设备压制辊轮经数控粗加工、淬火、二次精车、电镀等多步工序,精度高,跳动小,强度高,成型美观,无刮伤,无变形,充分保障您的产品质量。

• 交货快,售后积极

此设备交货期一般为30天,整机保修一年,终身维护。

|

|

规格--950琉璃瓦成型机

|

序号 |

主要组件 |

规格 |

备注 |

|

1 |

轴 |

调质45钢 |

约16道 |

|

2 |

辊轮 |

轴承钢 |

|

|

3 |

墙板 |

A3钢(18-20mm) |

|

|

4 |

传动 |

链条或齿轮箱 |

|

|

5 |

切断 |

液压剪切 |

|

|

6 |

电机功率 |

5.5KW |

|

|

7 |

控制系统 |

松下PLC,安川变频器 |

|

Main Technical Specification:

1.Material thickness: 0.3mm-0.8mm

2.Forming speed: 0-3m/min

3.Roll station:16 stations

4.Main power: 5.5kw

5.Hydraulic power: 7.5kw

6.Control system:PLC Panasonic

7.Drive: by chain

1. Single press model steel tile roll forming machine

1) Production Characteristic and use:

Steel tile roll forming machine adopts new station to increase the solidity of the machine; products are widely used in modern architecture roofing, the product increased the housing aesthetics.

2) Main Technical Specification:

①thickness: 0.3-0.8mm

speed: 5-6m/min

roll station: 16 stations (depend on the profile)

main power: 4.4KW Servo motor

hydraulic power: 4KW

control system: PLC Panasonic

Drive: by chain

②thickness: 0.3-0.8mm

speed: 2-4m/min

roll station: 16 stations (depend on the profile)

main power: 5.5KW

hydraulic power: 4KW

control system: PLC Panasonic

Drive: by chain