183-6235-6679

183-6235-6679 183-6235-6679

183-6235-6679

Main specification

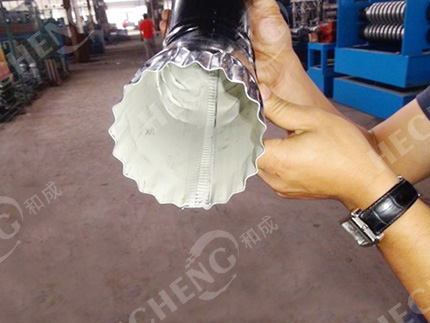

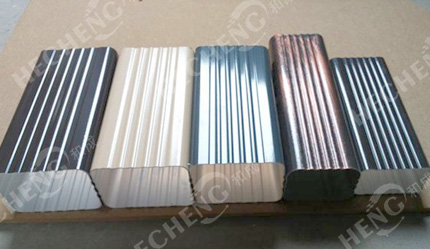

1. Suitable Material: Colored Steel plate, Galvanized steel

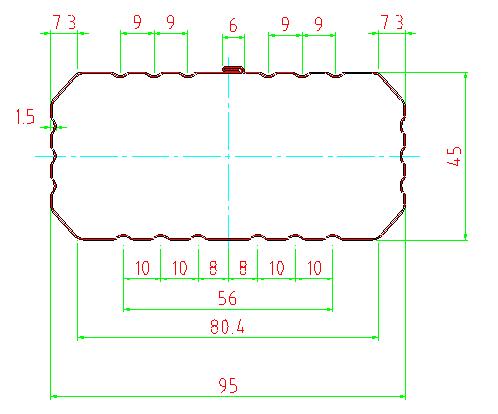

2. Width of the raw material: based on profile drawing

3. Thickness: 0.5-0.7mm

|

|

Profile drawing

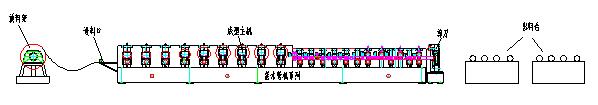

The Chart of Process Flow

Manual Uncoiler—Roll Forming—Cutting—out table

Machine Detailed Parameters

|

1 |

Coil width |

According to the final profile |

|

2 |

Rolling Speed |

0-15m/min |

|

3 |

Rolling Thickness |

0.5-0.7mm |

|

4 |

Control System |

PLC (Panasonic) as list in the note |

|

5 |

Un Coiler |

3T manual de-coiler |

|

6 |

Roller Stations |

20 stations |

|

7 |

Roller Material |

ASTM1045 chrome plated surface with chrome |

|

8 |

Shaft Material and DIA |

¢65mm, material:45# with quenching and tempering |

|

9 |

Post cutting |

Machine adopts hydraulic cutting system |

|

10 |

Material Of Cutting |

Cr12, 58-62 HRC hardness |

|

1 |

Maim Motor Power |

4kw |

|

12 |

Hydraulic Station Power |

5.5kw |

|

13 |

Hydraulic Pressure |

12-16Mpa adjustable |

|

14 |

Structure Of The Stations |

Wall panel |

|

15 |

Bending machine |

2.2kw, max bend angle: 90° |